› Flow to 50 ml/min

› Miniature design / 31.2 mm body width

› Stepper or DC / gear motor

› Lid close sensor / encoder

› Assembled Pico driver (for stepper version)

› Flow to 200 ml/min

› Flip-top tube change

› Miniature / compact design

› Floating saddle for enhanced tube life

› Stepper or DC / gear with optional encoder

› Flow to 200 ml/min

› Unique floating saddle

› Miniature / compact design

› Tube set or continuous tube

› Stepper or DC / gear with optional encoder

› Flow to 200 ml/min

› Cost effective

› Miniature / compact design

› Tube set or continuous tube

› Stepper or DC / gear with optional encoder

› Flow to 690 ml/min

› Dual channel

› Tube Sets (single and / or double)

› DC / Gear or Stepper Motor drive

› Pre-assembled drivers

› Encoders for closed loop control

› Flow to 1000 ml/min

› Versatile configurations

› Flip-top for rapid tube exchange

› Continuous tube

› Clip-on head

› DC / Gear, stepper or syncro drive

› Flow to 1000 ml/min

› Unique floating saddle

› Flip-top for rapid tube exchange

› Continuous tube

› Clip-on head

› DC / Gear, stepper or syncro drive

› Flow to 2000 ml/min

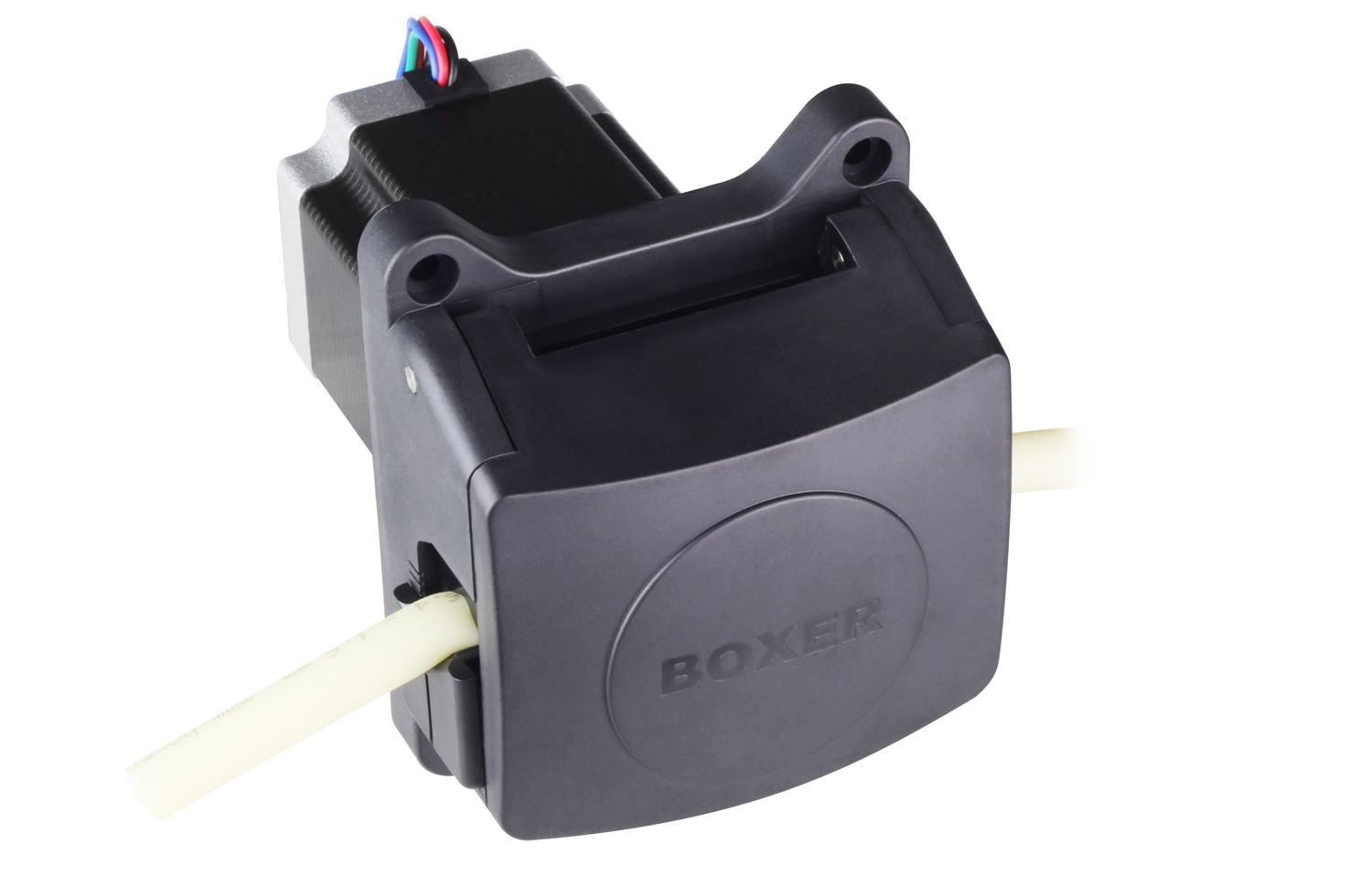

› Stepper motor drive

› Flip-top for rapid tube exchange

› Cost effective mouting to panel

› Lid and speed sensor options

› 2.4 to 8.0 mm ID tube, 1.6 and 2.4mm wall

› Flow to 2000 ml/min

› Stepper motor drive

› Flip-top for rapid tube exchange

› Detachable head, concealed mouting to panel

› Lid and 2 x speed sensor options

› 2.4 to 8.0 mm ID tube, 1.6 and 2.4mm wall

› For 1.0 mm wall tubing

› Flow to 56 ml/min per channel

› 1 to 12 channel

› Stepper motor controlled

› Range of driver and sensor options

› For 1.6 mm wall tubing

› Flow to 146 ml/min per channel

› 1 to 6 channel

› Stepper motor controlled

› Range of driver and sensor options